Jan 13, 2021 - Technology

An "emergency alert system" for PPE 3D printing

Add Axios as your preferred source to

see more of our stories on Google.

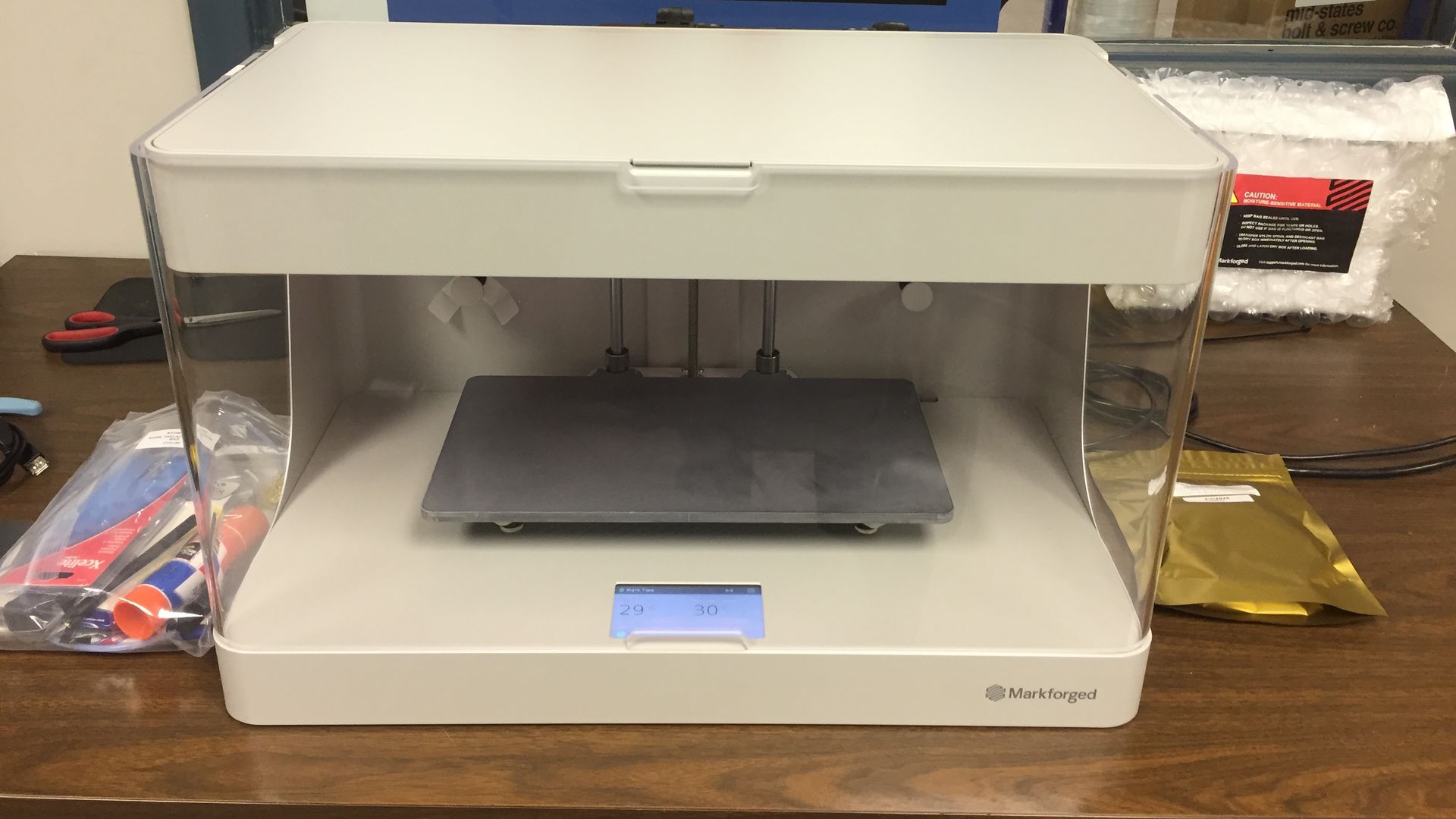

A 3D printer used for manufacturing personal protective equipment. Photo: International Engineering & Technologies, Inc.